Welcome to the Well-Stocked Garage! In this series, we take a look at how to organize and fill your workshop so you’re ready for any DIY job at a moment’s notice.

Today’s topic: There are many different types of spray lubricants on the market, each designed for specific applications and needs. It’s important to choose the right lubricant for the job, but how do you know which is which? Here’s a brief overview that should help.

ALUMINUM GREASE is formulated to provide excellent lubrication and protection at high temperatures. The addition of aluminum provides excellent lubrication and protection for a strong, durable lubricant that is perfect for use in heavy-duty applications. They can withstand high pressure, making them ideal for use in bearing, gears, and other moving parts.

CHAIN LUBRICANTS are water-resistant and specifically designed for use on chains and cables, such as those found on tractors, chainsaws, motorcycles, bicycles or conveyor systems. They help to reduce friction and wear on the chain by forming a thin, slippery film on the surface of the links. This film reduces the amount of heat and wear that is generated as the chain moves, which can help to extend the life of the chain.

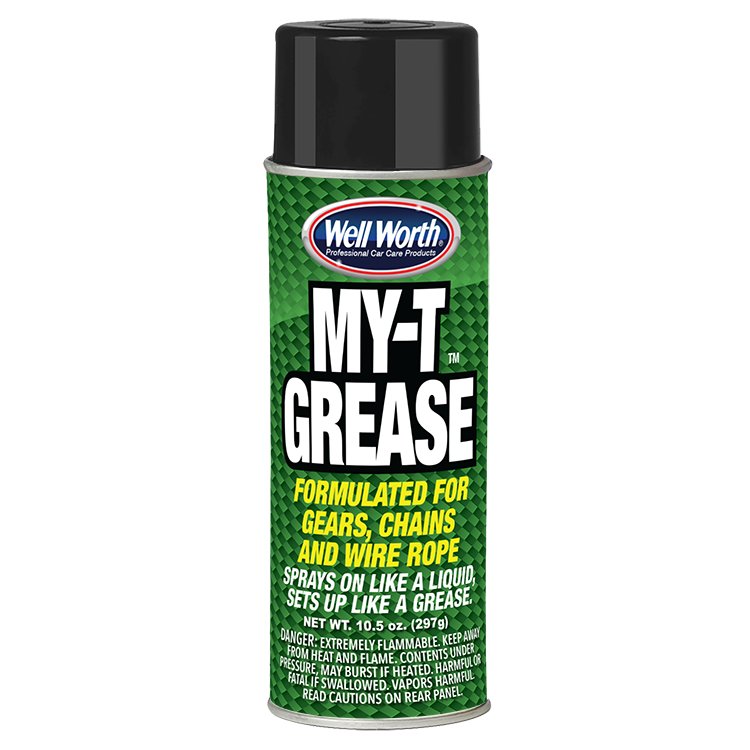

HYBRID GREASE is a multi-purpose type of grease that sprays on thin initially, and thickens up as it dwells.

LITHIUM GREASE is non-corrosive, can withstand heavy usage, has a high temperature resistance and adheres well to metal, making it the best choice for lubricating metal-to-metal situations such as bearings, gears, and hinges.

As the name suggests, MULTI-PURPOSE LUBRICANTS are designed to provide lubrication and protection for a wide range of materials, including metal, rubber, and plastic. You can use multi-purpose grease to lubricate metal parts, protect rubber and plastic, prevent corrosion on metal, and accomplish hundreds of maintenance and repair tasks around the home.

PENETRATING OILS are used to loosen or dissolve rust or other types of corrosion that have formed on metal surfaces. They are designed to penetrate small crevices and gaps in metal surfaces to reach and loosen the corrosion. Penetrating oils also contain lubricants that help to reduce friction and wear on metal surfaces, making them useful for maintenance and repair tasks.

SILICONE LUBRICANTS do not leave any oily residue and repel water. They are ideal for use on electrical components or any other parts that cannot be exposed to moisture.

SILICONE SPRAY is often used to lubricate metal surfaces, such as hinges, gears, and bearings, to help them move more smoothly and reduce wear. It is also used to lubricate rubber and plastic parts, such as seals and gaskets, to help them maintain their flexibility and prevent them from drying out or cracking.

Next time on the Well-Stocked Garage: Garage chores everyone forgets…that make all the difference!